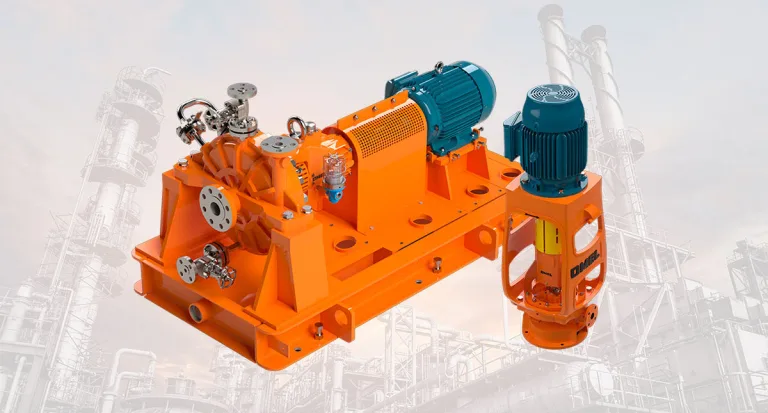

VRT/PA Roots Type Vacuum Pump

These are vacuum pumps that work in a similar way to trilobe blowers. They achieve a high compression ratio without any special problems by supplying air at room temperature, reaching final vacuums of up to 75 torr.

Operational Parameters

Capacity: _______________________ up to 3,500 m3/h

Vacuum: _____________________________ up to 75 torr

Project Features

- When a vacuum is created between the rotor and the casing, cold ambient air (or cold gas) enters through intake channels that are strategically placed in the vacuum pump body. This air flows through the machine together with the gas or air normally sucked in during the process, removing the heat generated during compression (from vacuum or negative pressure conditions to compression at near atmospheric or positive pressure).

- In the pump, the inlet is in an axially aligned position with the suction nozzle and, through two branches connected to the main chamber of the vacuum pump, it receives air at ambient external temperature through a pre-filter and a silencer.

- Six models of this type of machine are manufactured either for stationary use (vacuum centers) or for dynamic use in trucks for cleaning or suctioning water and sewage.

Advantages

- They achieve the necessary vacuum without the wear problems normally caused by “vane” type pumps and without the need to use water as in liquid ring vacuum pumps that require the use of a water tank with accessories that complement their operating system.

- Ideal for applications where it is necessary to transport oil-free gas with a vacuum level of up to 75 torr.

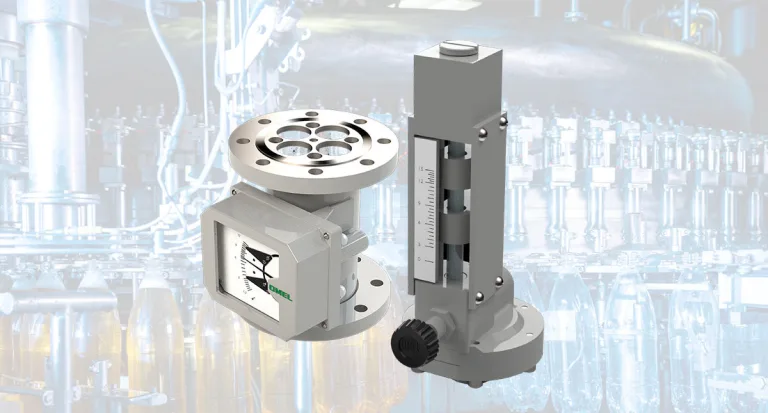

Auxiliary input for air intake

- In the photo below you can see the auxiliary inlet for the admission of air or cold gas which, being admitted through open passages in the body and connected to the atmosphere, cool the machine, allowing it to operate at the necessary operational vacuums.

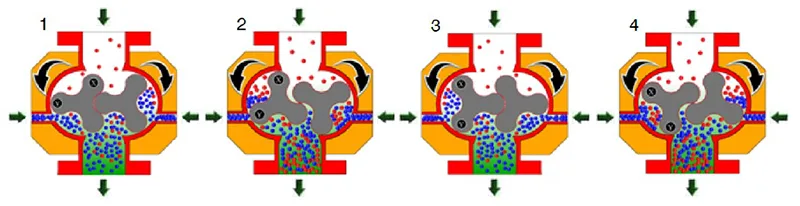

- This operating system can be more easily understood by observing the diagram below, where the blue dots represent the cold air or gas being admitted, and the red ones represent the air heated throughout the process, expelled after having mixed with the process gas.

Applications

- Suitable for use in installations where it is necessary to transport oil-free gas with a maximum vacuum level of 75 torr. (For installations requiring a vacuum between 0 and 50% (0 to 15” vacuum, the normal SRT series is perfect).

- Mobile or stationary units designed for the collection and treatment of liquid and/or solid waste, such as waste and sewage treatment in industry and city halls, etc.;

- Pneumatic transport installations in the chemical, pharmaceutical, food industries, etc.;

- Centralized vacuum systems (packaging, vacuum cleaning, etc.);

- Installations for closed-circuit transport, using nitrogen for example.

OMEL Original Parts and Technical Assistance

Get your pump repaired by the manufacturer!

By choosing OMEL’s after-sales service, you can count on the factory warranty, trained technicians, complete reports to diagnose the need for replacement parts, automated processes for manufacturing high-quality parts, and final performance tests to release pumps and instruments. With the safety, durability, and reliability of products repaired by OMEL, you will have excellent results in your industrial process and reduced operating costs.

Discover more OMEL products

OMEL offers a wide range of high-quality products for various applications.

Products offered include centrifugal pumps, vacuum pumps, metering pumps, roots blowers, ring compressors, rotameters, vacuum systems, and pinch valves.

Advantages of purchasing OMEL equipment

Fully national design and manufacturing

Original spare parts and ready delivery

Specialized technical assistance

OMEL Engineering available to develop custom projects

Technical support and online service

Service throughout the country