Pulp and Paper

Cellulose is obtained by transforming wood or other plant fibers into pulp, which is then bleached and dried. This pulp is mixed with water and additives and used as a raw material for the manufacture of various types of paper, such as newspaper, magazine, packaging, hygienic, sanitary, among others. The paper and pulp market is influenced by several factors, such as global demand, the availability and prices of commodities, and competitiveness among producing countries.

The segment is undergoing a transition with the growing demand for special and high added value papers, which are more suitable for new communication, information and education technologies such as digital printing and the manufacture of smart packaging.

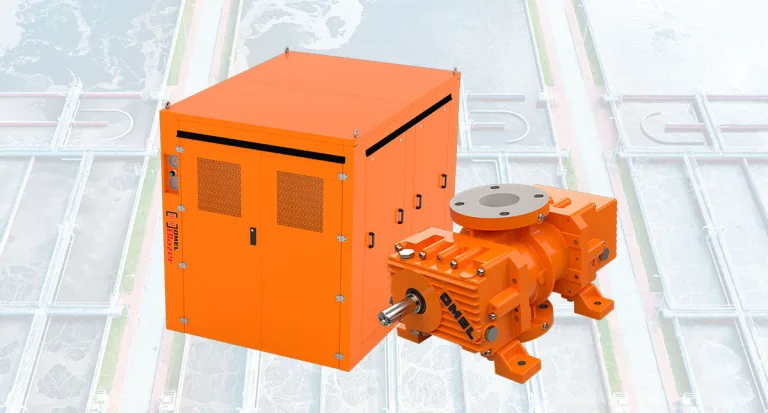

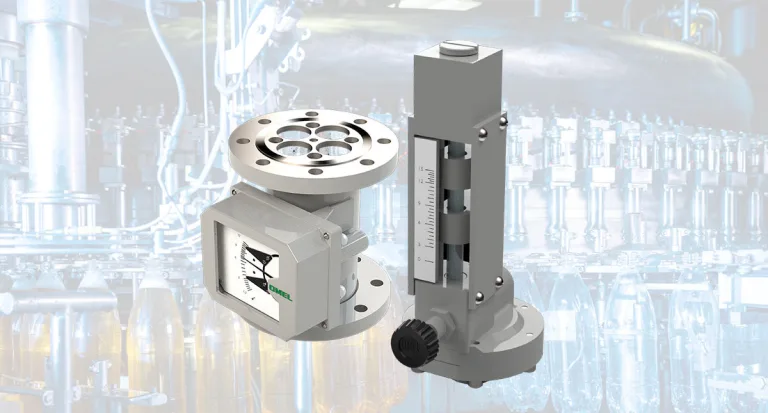

One of the main challenges facing the sector is to increase productivity and reduce costs and waste in processes while still meeting the standards and requirements of customers and regulatory agencies, contributing to sustainability and reducing environmental impacts. OMEL can help a lot in this regard by offering reliable, high-quality products and systems that improve and increase the performance of production processes on the factory floor and meet the needs of wastewater treatment plant applications with excellent cost/benefit.

Main applications

- Vacuum drying;

- In digesters, when pumping green, white and black liquors, light pulps, additive products such as kaolin, titanium dioxide, etc.;

- Transfer of liquids containing suspended solids;

- Effluent treatment;

- Instantaneous flow measurement of liquids and gases;

- Dosing of chemicals.