Centrifugal Pump UND/II-MAG

ANSI B73.3 Standard

Produced in Brazil by OMEL, for pumping toxic, dangerous, or harmful fluids to life or the environment. These pumps do not leak.

Operational Parameters

Capacity: ___________________________ up to 300m3/h

Total manometric head: _____________ up to 200m

Maximum Rotation: ___ 3600 RPM

Project Features

- Dimensions ANSI B73.1, pump interchangeable with sealed pumps of the same standard.

- Produced with bearing support or monoblock (only for pumps with 6″ and 8″ rotors).

- Bearing support in cast iron, with ball bearings and shaft sealed with bronze bearing seals (bearing seals also available in stainless steel).

- Meets ANSI B73.1-2003 and ANSI/HI 5.1 and 5.6 for magnetic pumps.

- Built-in self-cleaning filter (optional).

- The general assembly (external bearing support) can be removed without having to remove the pump from the line, while keeping the internal bearing system and containment sleeve assembled.

- Internal bearings made of (i) Sintered Silicon Carbide, (ii) Silicon Carbide with graphite, or (iii) Graphite, to be determined according to the physical-chemical properties of the pumped product. The stationary bearing bushing mounted on the shaft by means of tolerance compensation rings in Hastelloy C allows operation at any temperature.

- Neodymium iron magnets for use at pumping temperatures up to 120°C and samarium cobalt magnets for use at pumping temperatures up to 300°C.

Advantages

- One-piece, extra heavy-duty containment jacket made of corrosion-resistant Hastelloy C, which ensures safety and reduces losses due to eddy currents.

- Bearings and sleeves in pure sintered Silicon Carbide, which guarantee a long product life.

- Efficient internal fluid circulation, which guarantees the reduction of temperature generated by eddy currents.

- Monitoring of operational condition by measuring the temperature of the containment cup, providing protection in case of pump malfunction due to possible dry operation, interrupted recirculation, “flashing” of the pumped product, or decoupling of the magnets.

- Protective ring made of non-sparking material, protecting the friction containment sleeve of the external magnet assembly, in the event of operational failure of the external support bearings.

- Longest Mean Time Between Failures (MTBF).

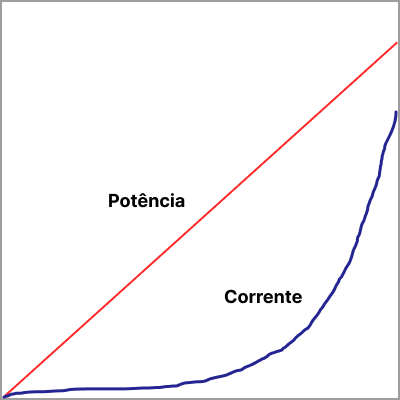

- Monitoring of the electrical power consumed by the pump, which enables its immediate shutdown in the event of any operational problems. If the pumping temperature varies greatly, monitoring by temperature is not the most appropriate. In this case, dry running can also be detected by flow switches, pressure switches, or power/current sensors. A power sensor (load sensor) is preferable to a current sensor, as the former will vary linearly even under low load conditions (see graph); consult OMEL’s application experts for more information.

Applications

- In chemical and petrochemical processes, in the pharmaceutical industry, in the nuclear industry, in continuous or discontinuous processes.

- Unloading of tanks and vehicles transporting sensitive liquids

- In the transfer and recirculation of thermal fluids.

- In the pumping of acidic, flammable, pure, explosive, poisonous, atmosphere-sensitive, lethal, aggressive, toxic, contaminating, contaminated, harmful, hot, cold, pyrogenic, cryogenic, acidic, and difficult to seal fluids.

- In applications where leaks cannot occur, such as pumping acids, alcohols and glycols, alkalis, hydrocarbons, heat transfer fluids, hydrocarbons, nitrogen and sulfur compounds, salts and chemicals such as formaldehyde, ether, TDI, MDI, acetone, acetic anhydride, detergents, monoglycerides, vegetable oils, demineralized water, heavy water, propylene oxide, methyl chloride, lead acetate, cyanides, and freon.

OMEL Original Parts and Technical Assistance

Get your pump repaired by the manufacturer!

By choosing OMEL’s after-sales service, you can count on the factory warranty, trained technicians, complete reports to diagnose the need for replacement parts, automated processes for manufacturing high-quality parts, and final performance tests to release pumps and instruments. With the safety, durability, and reliability of products repaired by OMEL, you will have excellent results in your industrial process and reduced operating costs.

Discover more OMEL products

OMEL offers a wide range of high-quality products for various applications. Products offered include centrifugal pumps, vacuum pumps, metering pumps, roots blowers, ring compressors, rotameters, vacuum systems, and pinch valves.

Advantages of purchasing OMEL equipment

Fully national design and manufacturing

Original spare parts and ready delivery

Specialized technical assistance

OMEL Engineering available to develop custom projects

Technical support and online service

Service throughout the country