HDRP Centrifugal Pump (OH2)

API Standard - 610

HDRP Series centrifugal pumps have special impellers and volutes and are suitable for continuous operations with small capacities at high manometric heads. Under these conditions, conventional centrifugal pumps could not operate without the installation of a system to control capacity or recirculate excess flow via bypass.

The models in this series comply with API 610 standard (latest edition) and can also be supplied in the In-Line OH3 (HDR/IL) or vertical “Sump Pump” VS4 (HDRP/VT) version.

Operational Parameters

Capacity: ___________________________ 0,25 ~ 25m3/h

Total manometric height: _____________ up to 300m

Maximum Rotation: ______________________ 3600 RPM

Temperature: __________________________ -100ºC ~ +400ºC

Pressure: _______________________________ up to 51 bar

Project Features

- Full compliance with the latest edition of API 610 standard.

- Complete range of materials according to API 610.

- Heavy duty bearing housing.

- Heavy duty shaft, low L3/D4 to minimize deflection, optimizing the life of mechanical seals.

- Maximum interchangeability of components.

- Improved convection cooling by adopting suitably located and sized fins.

- Dry axis.

- Open rotor specifically for low flow work and with compatible hydraulics.

Advantages

- Pumping of small flows and high manometric height without the need for excess flow recirculation lines, or high-cost high-speed pumps.

- Semi-open radial type impeller, designed to reduce axial loads to a minimum regardless of the suction pressure.

- It does not have wear rings and its large axial clearance allows it to operate within its operating temperature range without the risk of seizure.

- Back-pull-out pumps for ease of maintenance.

- Large seal box to accommodate all types of mechanical seals.

Applications

- In the pumping of refined petroleum products: diesel, gasoline, kerosene, naphtha, column reflux, column charge, heavy gas oil, reboilers, residual flash, stabilizer feed, stabilizer reflux, fuel mixtures, heat transfer, hot oil, column bottoms, injection, hydrocarbon transfer, boiler circulation, sour water, boiler feed, etc.

OMEL Original Parts and Technical Assistance

Get your pump repaired by the manufacturer!

By choosing OMEL’s after-sales service, you can count on the factory warranty, trained technicians, complete reports to diagnose the need for replacement parts, automated processes for manufacturing high-quality parts, and final performance tests to release pumps and instruments. With the safety, durability, and reliability of products repaired by OMEL, you will have excellent results in your industrial process and reduced operating costs.

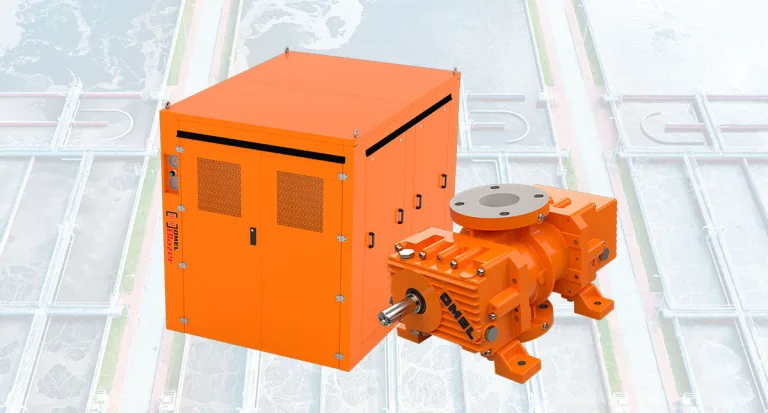

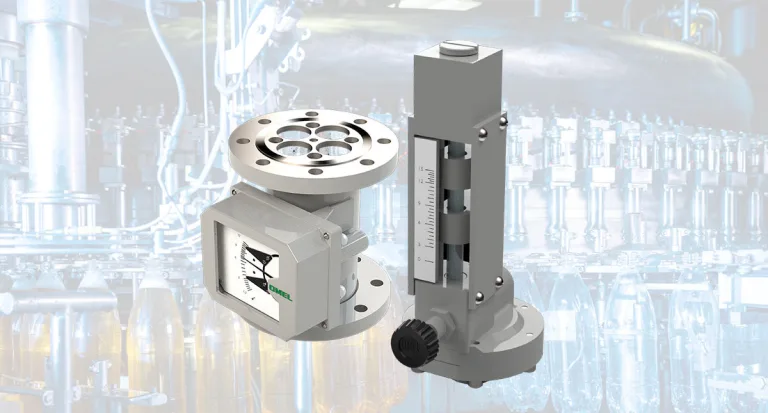

Discover more OMEL products

OMEL offers a wide range of high-quality products for various applications. Products offered include centrifugal pumps, vacuum pumps, metering pumps, roots blowers, ring compressors, rotameters, vacuum systems, and pinch valves.

Advantages of purchasing OMEL equipment

Fully national design and manufacturing

Original spare parts and ready delivery

Specialized technical assistance

OMEL Engineering available to develop custom projects

Technical support and online service

Service throughout the country