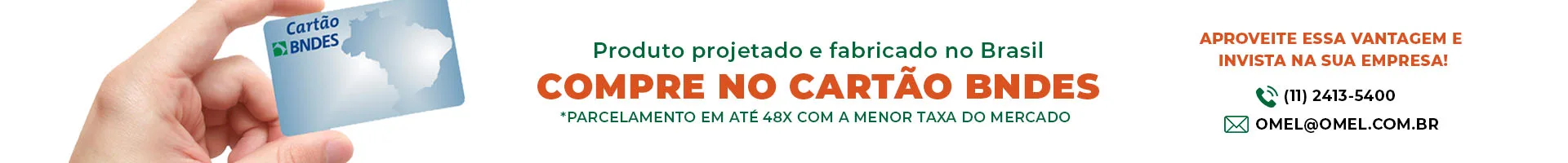

NSP Dosing Pump

API Standard - 675

NSP pumps are diaphragm metering pumps used for high precision services with a maximum theoretical capacity that can vary linearly from 10 to 100%, allowing dosages with errors of up to 1%.

Operational Parameters

Capacity: _________________________ up to 5.500 l/h (per head)

Pressure: _____________________________ up to 340 bar

Temperature: _______________________ -40ºC ~+400ºC

Project Features

- NSP pumps can be used as pumps, flow meters and/or control elements.

- When used as final control elements, they can be controlled remotely by process control instruments, electrical or through frequency inverters.

- Designed to operate with a wide variety of products, NSP pumps can be used in severe chemical processes, such as pumping viscous liquids, at high temperatures, corrosive, flammable and toxic liquids, among others.

- Heads: made of stainless steel AISI 304 or 316, HASTELLOY B or HASTELLOY C, ALLOY-20, AISI 304L or 316L and plastic materials such as PVC, PTFE, polypropylene, resins and epoxy, among other materials subject to consultation.

- Diaphragms: made of PTFE or stainless steel and for tubular diaphragms in rubbers, such as neoprene, BUNA-N and Viton, among other materials subject to consultation. Triple diaphragms for high safety.

- Check valves: made of stainless steel AISI 304 or 316, HASTELLOY B or HASTELLOY C, Alloy-20, AISI 304L or 316L and plastic materials such as PVC, PTFE, polypropylene, resins and epoxy, among other materials subject to consultation.

- Balls: made of 316 stainless steel, HASTELLOY B or HASTELLOY C, ALLOY-20, ceramic, sara, and PTFE, among other materials subject to consultation.

- Special Cases: versions of heads and valves with heating chambers can be supplied, special executions for cooling and special executions can be made on request. Consult our technical department.

Advantages

- Accurate dosage;

- Robust construction;

- Meets API-675 requirements;

- Various pump head mounting options;

Applications

- The NSP pump series can be used in applications in the chemical and petrochemical, food, sanitation segments, among others, and can pump corrosive, toxic and radioactive liquids, subject to consultation for further information.

- Single diaphragm heads: suitable for simple applications.

- Triple diaphragm heads: designed for hazardous, flammable, toxic liquids or those requiring an extra protection system.

NSP Metering Pump • Triple Diaphragm

Aiming to offer greater operational safety and protection to the environment and human beings, OMEL developed the NSP Triple Diaphragm model (patented).

This metering pump model has a set of three diaphragms (made of PTFE or stainless steel) where one diaphragm remains in contact with the pumped liquid, another diaphragm in contact with the oil or pumping fluid and a third element is placed between the two previous diaphragms, acting as a separator. These three elements, together, form a protection that facilitates the replacement of parts in the event of maintenance being required.

The assembly creates a vacuum between the diaphragms and in the event of a leak, the absence of vacuum will be indicated by the pump’s vacuum gauge, which can be equipped with an alarm system, and more sophisticated systems can be used, such as a PLC – Programmable Logic Controller. If a rupture occurs, either in the diaphragm in contact with the pumped product or in the diaphragm in contact with the oil, it allows the pump to continue operating until the diaphragm assembly is replaced in an emergency or the pump is stopped.

OMEL Original Parts and Technical Assistance

Get your pump repaired by the manufacturer!

By choosing OMEL’s after-sales service, you can count on the factory warranty, trained technicians, complete reports to diagnose the need for replacement parts, automated processes for manufacturing high-quality parts, and final performance tests to release pumps and instruments. With the safety, durability, and reliability of products repaired by OMEL, you will have excellent results in your industrial process and reduced operating costs.

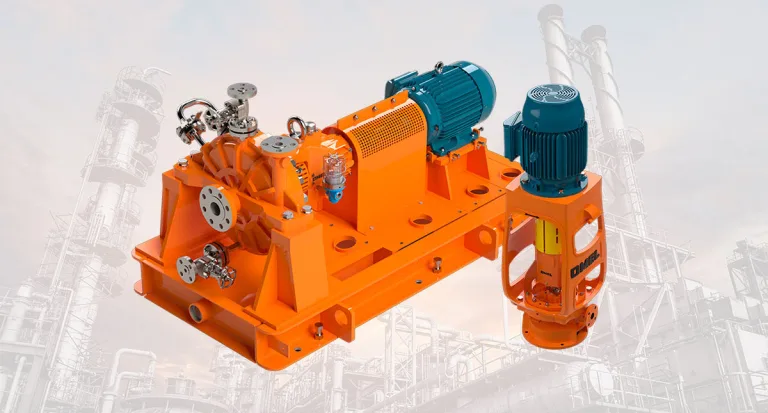

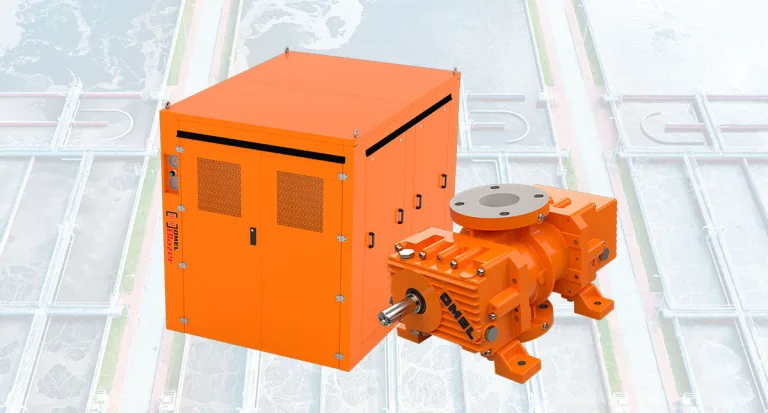

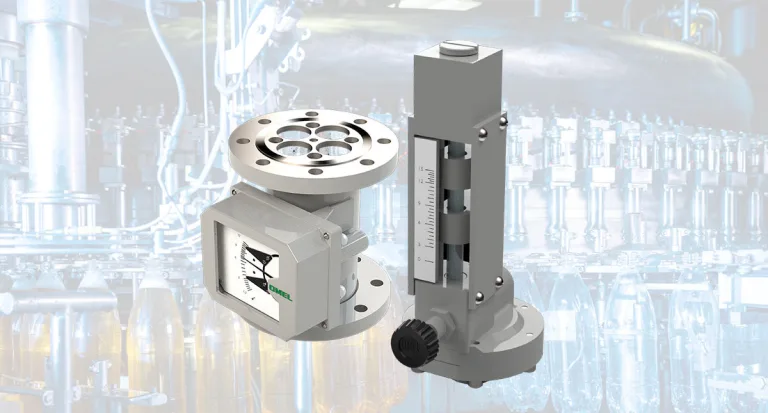

Discover more OMEL products

OMEL offers a wide range of high-quality products for various applications.

Products offered include centrifugal pumps, vacuum pumps, metering pumps, roots blowers, ring compressors, rotameters, vacuum systems, and pinch valves.

Advantages of purchasing OMEL equipment

Fully national design and manufacturing

Original spare parts and ready delivery

Specialized technical assistance

OMEL Engineering available to develop custom projects

Technical support and online service

Service throughout the country