Pulsation Dampeners • For OMEL Pumps

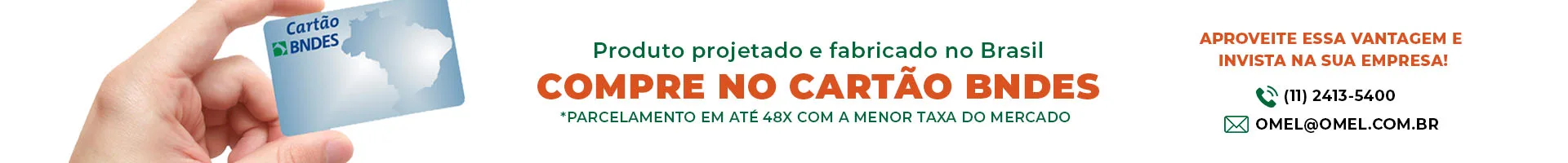

OMEL NSP and NSP/P series metering pumps provide a pulsating flow due to their reciprocating positive displacement characteristics. OMEL has two types of dampers specially developed to be coupled to these pump series.

The basic function of OMEL Pulsation Dampers is to eliminate these

pulsations in applications with metering pumps, linearizing the fluid displacement flow, which will become practically continuous.

Project Features

- The linearity of the flow prevents vibrations in the dosing system pipes;

- Protecting elements such as valves, filters and other accessories installed in the discharge line;

- The metering pump works more smoothly, increasing the useful life of its components;

- Reduces fluid agitation while preserving its physical-chemical characteristics;

- Provides energy savings by eliminating pressure variations in the line;

- Prevents potential water hammer in applications with quick-lock valves.

- Bi-partite body in cast iron or stainless steel. Pulsation dampers can be manufactured in other alloys.

Advantages

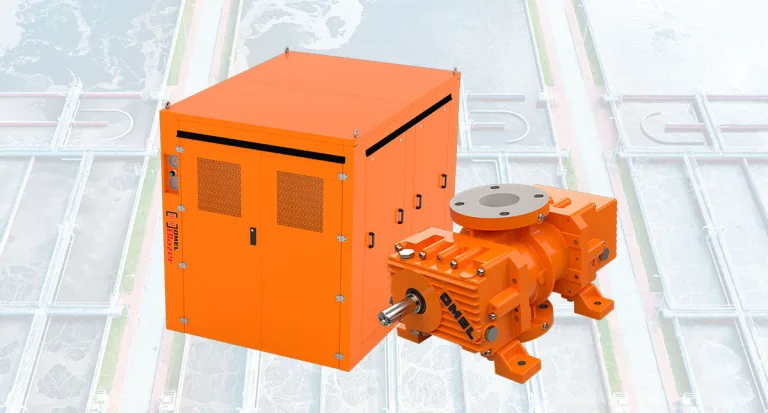

ASD Model – Without Diaphragm

The air contained in the shock absorber is compressed by the pumped liquid, thus creating a cushion whose pressure is balanced with that developed by the pump, absorbing the pulsations.

For better performance of this type of shock absorber, it is recommended to inject air or neutral gas into its upper part, equalizing the internal pressure with the discharge pressure exerted by the pump.

Advantages:

- Lower investment;

- High operating pressure range;

Disadvantages:

- Larger space required

- Lower income

- The pumped liquid comes into direct contact with the gas

AD Model – With Diaphragm

The principle is identical to that of the “ASD” model, with the difference that the pumped liquid is separated from the gas by a diaphragm, avoiding direct contact and consequently preventing its solubilization in the liquid.

Advantages:

- Less space required;

- Higher yield;

- The pumped liquid does not come into direct contact with the gas;

Disadvantages:

- Greater investment;

- Limited operating pressure range;

OMEL Original Parts and Technical Assistance

Get your pump repaired by the manufacturer!

By choosing OMEL’s after-sales service, you can count on the factory warranty, trained technicians, complete reports to diagnose the need for replacement parts, automated processes for manufacturing high-quality parts, and final performance tests to release pumps and instruments. With the safety, durability, and reliability of products repaired by OMEL, you will have excellent results in your industrial process and reduced operating costs.

Discover more OMEL products

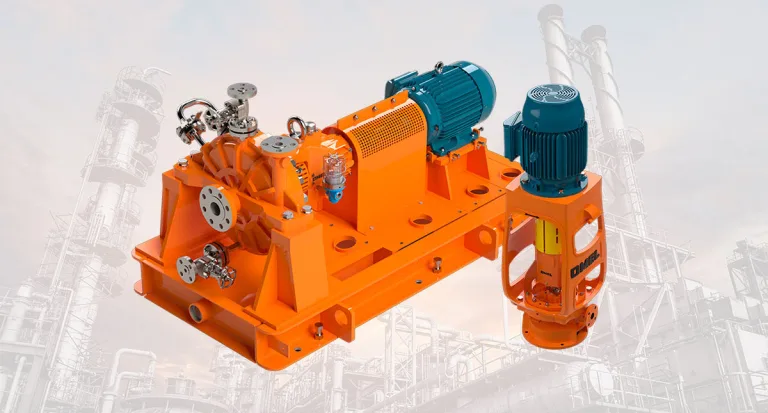

OMEL offers a wide range of high-quality products for various applications.

Products offered include centrifugal pumps, vacuum pumps, metering pumps, roots blowers, ring compressors, rotameters, vacuum systems, and pinch valves.

Advantages of purchasing OMEL equipment

Fully national design and manufacturing

Original spare parts and ready delivery

Specialized technical assistance

OMEL Engineering available to develop custom projects

Technical support and online service

Service throughout the country