UND/III-AE Centrifugal Pump

The UND/III-AE model process pump line is specifically designed to provide superior performance in general and chemical process industries that require pumping services that require self-priming.

Operational Parameters

Capacity: ___________________________ up to 350m3/h

Total manometric head: _____________ up to 120m

Total effective suction height: ____________ up to 6m

Maximum Rotation: ______________________ 3600 RPM

Project Features

- Heavy-Duty Shaft and Bearings Shaft designed for minimum deflection, less than 0.005″ (0.13 mm) at seal faces. Bearings sized for long life under harsh operating conditions.

- Compact one-piece housing design. Eliminates the need for a separate priming chamber, air separator or valves. Self-ventilated on-axis discharge. Back pull-out design.

- Sealing flexibility: SUPERBOX or CONEDOX sealing boxes or standard chambers for maximum sealing flexibility to meet any service conditions.

- Lubrication flexibility: allows, in addition to the normal splash system, the adoption of spray or mist lubrication (oil mist).

- Semi-open impeller recognized as the best option for services in process industries handling solids, viscous, corrosive and abrasive materials. The back-pumping vanes help minimize seal chamber pressure.

- Adapter between bearing support and housing in nodular cast iron with mechanical resistance equivalent to that of carbon steel, ensuring greater safety.

Advantages

- One-piece housing with integrated priming chamber;

- Does not require a suction check valve;

- Fast priming time;

- Positive liquid retention in the housing under siphon conditions;

- Self-purging of vapors;

- Design aiming at rear removal of the bearing support (back pull-out);

- Parts interchangeable with the UND/III model;

- External axial adjustment of the rotor.

Applications

- Industrial collector wells

- Depletion of mines and galleries

- Chemical transfer;

- Removal of water from the holds of vessels;

- Tanker truck unloading;

- Oil transfer filter systems;

- Aircraft refueling;

- Column bottoms and reflux.

OMEL Original Parts and Technical Assistance

Get your pump repaired by the manufacturer!

By choosing OMEL’s after-sales service, you can count on the factory warranty, trained technicians, complete reports to diagnose the need for replacement parts, automated processes for manufacturing high-quality parts, and final performance tests to release pumps and instruments. With the safety, durability, and reliability of products repaired by OMEL, you will have excellent results in your industrial process and reduced operating costs.

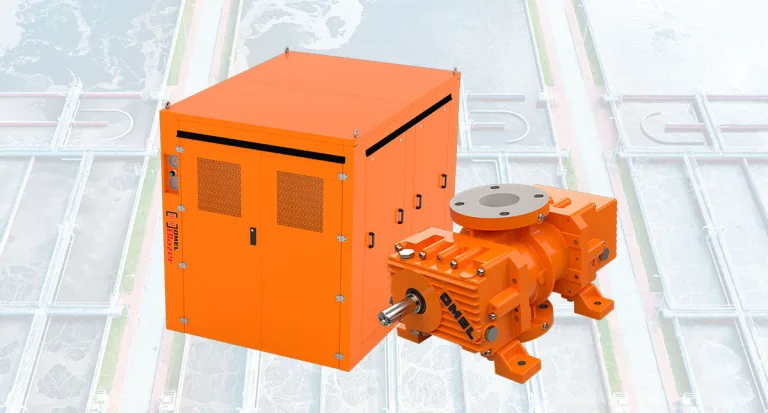

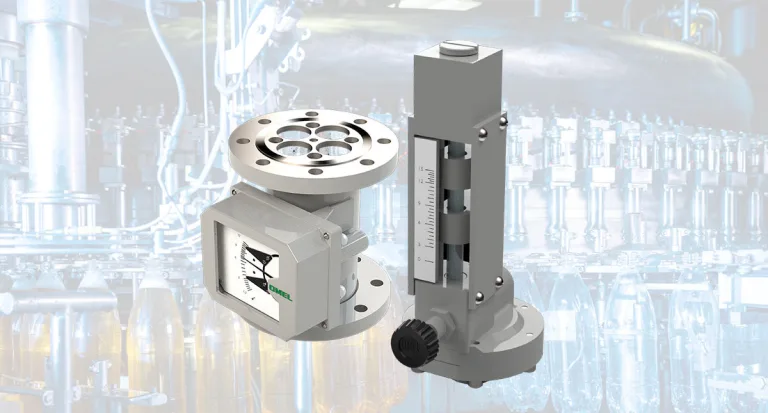

Discover more OMEL products

OMEL offers a wide range of high-quality products for various applications. Products offered include centrifugal pumps, vacuum pumps, metering pumps, roots blowers, ring compressors, rotameters, vacuum systems, and pinch valves.

Advantages of purchasing OMEL equipment

Fully national design and manufacturing

Original spare parts and ready delivery

Specialized technical assistance

OMEL Engineering available to develop custom projects

Technical support and online service

Service throughout the country