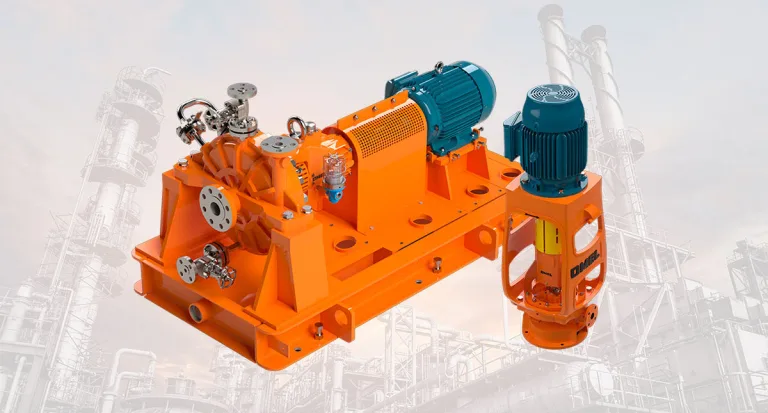

Metering Pump NSP/M – NSP/MP

API Standard - 675

This is a series of small-capacity metering pumps

with hydraulically balanced diaphragms, which isolate the pumped product from the mechanical part of the pump and can also be built in piston versions (NSP/MP).

These are diaphragm and piston pumps used for high-precision services

with a maximum theoretical capacity that can vary linearly

from 20 to 100%, allowing dosages with errors of no more than 1%.

Operational Parameters

Capacity: _________________________ 0,26 ~ 13 l/h (per head)

Pressure: _____________________________ up to 200 bar

Temperature: _______________________ -40ºC ~+400ºC

Project Features

- Hydraulically balanced diaphragm: with the oil bath, the piston hydraulically moves the diaphragm alternatively. This, in turn, based on its displacement, moves the liquid to be pumped, which will be sucked in by the suction check valve (during the piston’s suction movement) and discharged through the discharge check valve (during the piston’s compression movement). The diaphragm isolates the product to be pumped, confining it between the pumping chamber and the check valves. These are the only parts of the pump that come into contact with the pumped product.

- Heads: made of stainless steel AISI 304 or 316, HASTELLOY B or HASTELLOY C, MONEL or even plastic materials such as PVC, PTFE and polypropylene, among other materials subject to consultation.

- Diaphragms: stainless steel, PTFE or polypropylene, among other materials subject to consultation.

- Check valves: made of stainless steel AISI 304 or 316, HASTELLOY B or HASTELLOY C, MONEL or even PVC, PTFE and polypropylene, among other materials subject to consultation.

- Balls: made of AISI 304 or 316 stainless steel, HASTELLOY B or HASTELLOY C, MONEL or even PVC, PTFE and polypropylene, among other materials subject to consultation.

Advantages

- Pumping heads supplied with single, double or multiple ball check valves.

- Disc or cone type check valves can be fitted, with or without spring loading. (optional)

- Greater performance was achieved thanks to the versatility of piston seal materials, which can be used: common graphite gaskets, PTFE gaskets, PTFE “V” rings or others, according to the application needs.

- Lubrication can be done by the liquid itself or by clean liquid from an external source, depending on the fluid being pumped.

Applications

- The NSP/M and NSP/MP pump series can be used in applications in the chemical and petrochemical, food, sanitation, and other segments, and can pump corrosive, toxic, and radioactive liquids, subject to consultation for further information.

- Single diaphragm heads: suitable for simple applications.

- Triple diaphragm heads: designed for hazardous, flammable, toxic liquids or those requiring an extra protection system.

OMEL Original Parts and Technical Assistance

Get your pump repaired by the manufacturer!

By choosing OMEL’s after-sales service, you can count on the factory warranty, trained technicians, complete reports to diagnose the need for replacement parts, automated processes for manufacturing high-quality parts, and final performance tests to release pumps and instruments. With the safety, durability, and reliability of products repaired by OMEL, you will have excellent results in your industrial process and reduced operating costs.

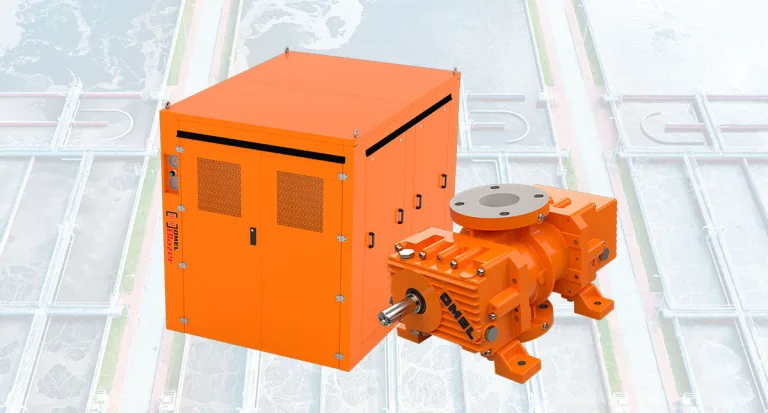

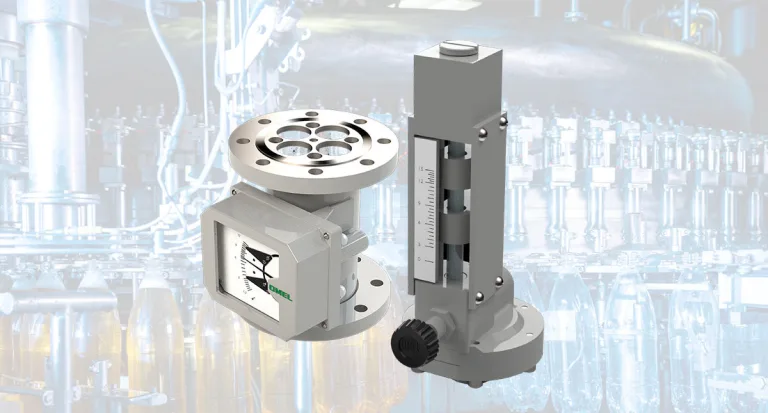

Discover more OMEL products

OMEL offers a wide range of high-quality products for various applications.

Products offered include centrifugal pumps, vacuum pumps, metering pumps, roots blowers, ring compressors, rotameters, vacuum systems, and pinch valves.

Advantages of purchasing OMEL equipment

Fully national design and manufacturing

Original spare parts and ready delivery

Specialized technical assistance

OMEL Engineering available to develop custom projects

Technical support and online service

Service throughout the country