NT Pinch Valves

The NT and NT/AP Series valves offer a simple and safe way to control the flow of material in a pipeline. Only the tubular diaphragm (hose) comes into contact with the fluid, thus increasing the life of the other components. Due to the flexibility of the tubular diaphragm, the system will always be completely closed, even in the presence of solid materials. For this reason, there will be no pressure losses or accumulation of materials inside the valve, facts of extreme

importance when operating with food products, fluids with large amounts of suspensions and minerals, among others.

Operational Parameters

Working pressure: ___ ___________ up to 17kg/cm2 (Room temp.)

Gauges: ___ _________________________ from 1/2” ~ 24

Temperature: _______________________________________ Natural rubber diaphragm: 80ºC

Synthetic rubber diaphragm: 90ºC

Synthetic rubber diaphragm: 90ºC

Project Features

- Total absence of gaskets

- Positive closure even on solids.

- Up to 8” diameter gauge, NT valves are supplied in a fully closed construction with internal parts in nodular cast iron, steel stem and external body in cast iron or aluminum (optional); from diameter 10” to diameter 16” the valves are supplied in the same construction materials, but in open execution; from diameter 18” to diameter 24”, they also use the same construction materials in open execution but with actuation by means of a built-in reducer.

- NT/AP valves are supplied in a fully closed construction up to a diameter of 2.1/2”; from a diameter of 3” to 16” the execution is open, with valves with a diameter of 16” and above being actuated by means of a built-in reducer.

Advantages

- Free passage, without obstructions.

- Zero pressure drop.

- No mechanical parts other than the diaphragm in contact with the controlled product.

- Long lasting under severe conditions.

- Only one wear component – the tubular diaphragm (hose).

- Quick and simple maintenance.

- They are cast and are much more resistant, unlike other brands, which are made of laminates or welded and are more susceptible to twisting and breaking.

Applications

- NT and NT/AP valves are used in applications in different segments such as the chemical industry, mining, ceramics, water and wastewater treatment, offshore platforms, cement and occasionally in the food industry (with sanitary rubber hose), among others.

OMEL Original Parts and Technical Assistance

Get your pump repaired by the manufacturer!

By choosing OMEL’s after-sales service, you can count on the factory warranty, trained technicians, complete reports to diagnose the need for replacement parts, automated processes for manufacturing high-quality parts, and final performance tests to release pumps and instruments. With the safety, durability, and reliability of products repaired by OMEL, you will have excellent results in your industrial process and reduced operating costs.

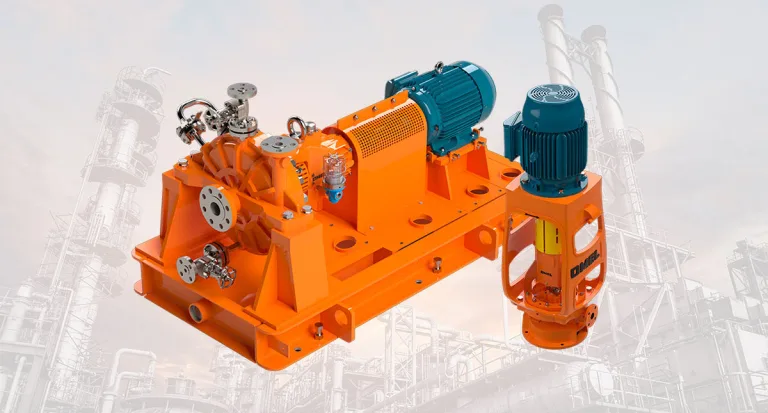

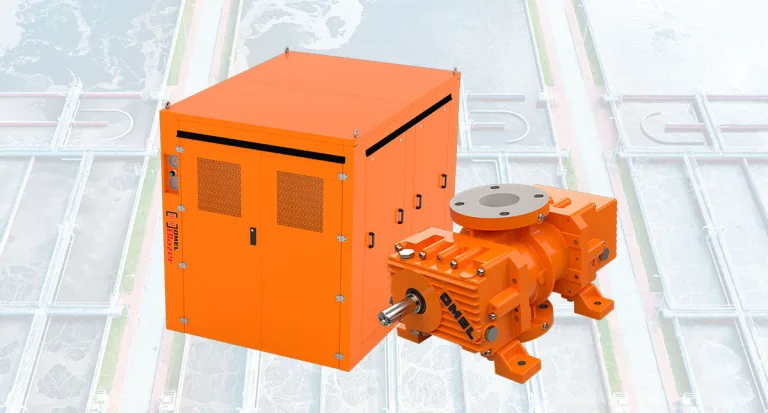

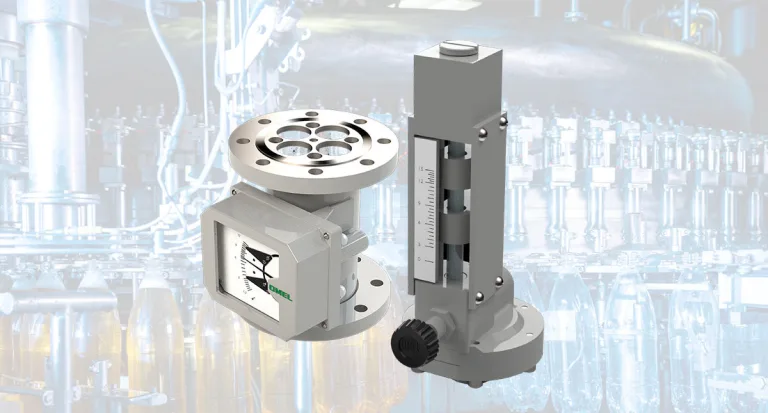

Discover more OMEL products

OMEL offers a wide range of high-quality products for various applications.

Products offered include centrifugal pumps, vacuum pumps, metering pumps, roots blowers, ring compressors, rotameters, vacuum systems, and pinch valves.

Advantages of purchasing OMEL equipment

Fully national design and manufacturing

Original spare parts and ready delivery

Specialized technical assistance

OMEL Engineering available to develop custom projects

Technical support and online service

Service throughout the country