Rotameter P

The P model rotameters are built in 1/8”, 1/4” and 1/2” gauges for reading low gas or liquid flows. Made in three versions, with useful scales of 60 mm (1P5), 150 mm (3P5) with the same flow ranges, and 250 mm (4P5) for higher flows. When coupled to differential pressure regulators, the rotameters can control liquid or gas flows even with pressure variations upstream or downstream of the device.

Operational Parameters

Capacity: _____________________

__________________ Water: up to 600 nl/h

Air: up to 15 nm3/h

__________________

Air: up to 15 nm3/h

Pressure: ____________________________ up to 15 kgf/cm2

Temperature: ____________________________ up to 120 ºC

Sizes: ____________________________ 1/8” to 1/2”

Project Features

- Floats available in different materials and measuring tube dimensions, to obtain different flow rates, subject to consultation.

- Accessories available such as: needle valve, check valve, flow alarms, panel installation, subject to consultation.

- The connections are female NPT threaded and can be positioned 360°, with 90° intervals.

- Industrial standard accuracy: ± 10% and ± 2% of full scale for models 1P5, 3P5 and 4P5

- Repeatability: 0.5% of full scale.

- Fully protected borosilicate tube.

Advantages

- Interchangeable floats and measuring tubes for rotameters of the same size.

- Sealing allows replacement of the measuring tube without removing the rotameter from the line.

- PTFE stops inside the measuring tube prevent loss of the float during removal (for models 1P5 and 3P5).

- Calibration according to customer needs for direct reading.

Applications

- They are ideal for purging systems, bearing lubrication, level and flow control, gas flow indication in chromatographs and instantaneous flow measurement of liquids and gases.

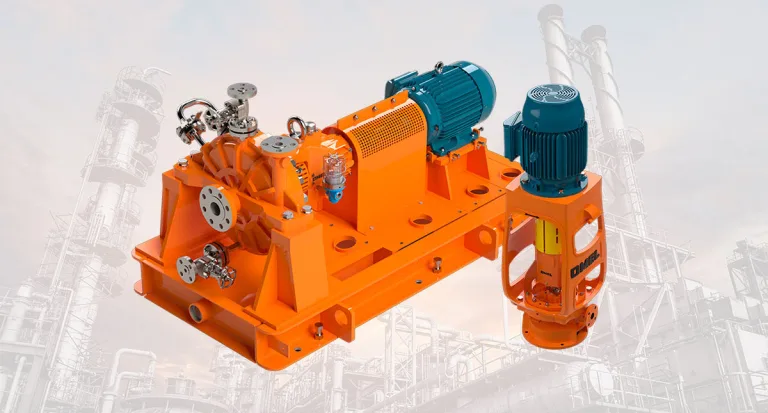

OMEL Original Parts and Technical Assistance

Get your pump repaired by the manufacturer!

By choosing OMEL’s after-sales service, you can count on the factory warranty, trained technicians, complete reports to diagnose the need for replacement parts, automated processes for manufacturing high-quality parts, and final performance tests to release pumps and instruments. With the safety, durability, and reliability of products repaired by OMEL, you will have excellent results in your industrial process and reduced operating costs.

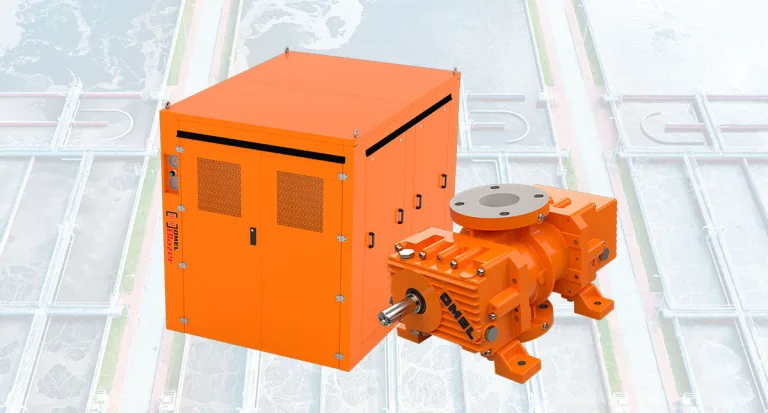

Discover more OMEL products

OMEL offers a wide range of high-quality products for various applications.

Products offered include centrifugal pumps, vacuum pumps, metering pumps, roots blowers, ring compressors, rotameters, vacuum systems, and pinch valves.

Advantages of purchasing OMEL equipment

Fully national design and manufacturing

Original spare parts and ready delivery

Specialized technical assistance

OMEL Engineering available to develop custom projects

Technical support and online service

Service throughout the country