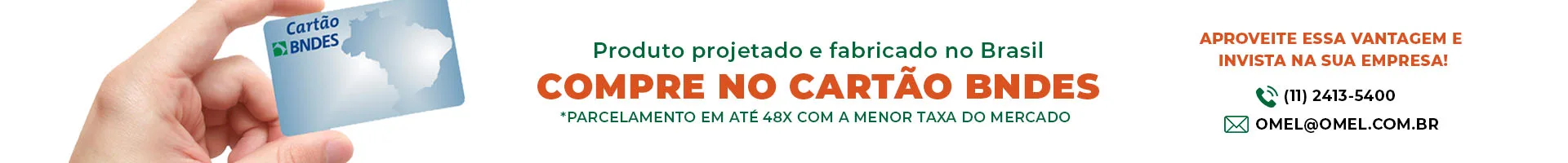

Liquid Ring Compressor Series BKA – BKN – BKM

BKA and BKN 1-stage liquid ring compressors with rotor between bearings. Sealing with mechanical seal or packing glands. BKM are 1-stage monobloc compressors with mechanical seal sealing.

Operational Parameters

Capacity: _____________________ up to 10.350 m3/h

Pressure: _________________________ up to 1,6 bar

Maximum Rotation: ________________ 3500 RPM

Project Features

- The liquid ring compressor operates with auxiliary liquid (usually water) that alternately fills and leaves the rotor alveoli. There are openings in the walls of the side plates that allow communication with filled or empty alveoli, respectively. Thus, while air (or gas) is sucked in through one opening, it is discharged through the other, with the continuous and regular transport of air (or gas) occurring through compression. The maximum degree of compression that can be achieved depends on the energy acquired by the liquid in motion, its nature, and the rotation speed of the rotors.

Advantages

- Completely oil-free compression;

- High operational reliability;

- Availability of construction in anti-corrosive alloys;

- Insensitive to impurities or small foreign bodies aspirated;

- Lower gas outlet temperature than other compressor types;

- Low noise and vibration.

Applications

- Liquid ring compressors have applications in a wide range of industrial processes, such as: air and gas compression in general, bubbling in fermentation tanks and fermenters, agitation of baths and liquids in general, air supply to burners, for use in the chemical, food, and other industries.

OMEL Original Parts and Technical Assistance

Get your pump repaired by the manufacturer!

By choosing OMEL’s after-sales service, you can count on the factory warranty, trained technicians, complete reports to diagnose the need for replacement parts, automated processes for manufacturing high-quality parts, and final performance tests to release pumps and instruments. With the safety, durability, and reliability of products repaired by OMEL, you will have excellent results in your industrial process and reduced operating costs.

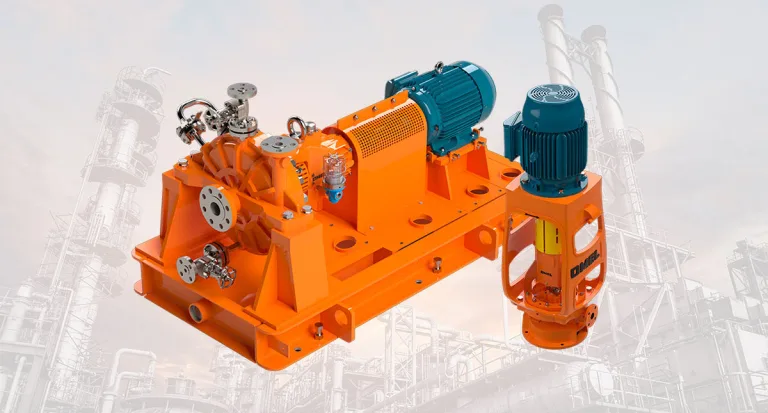

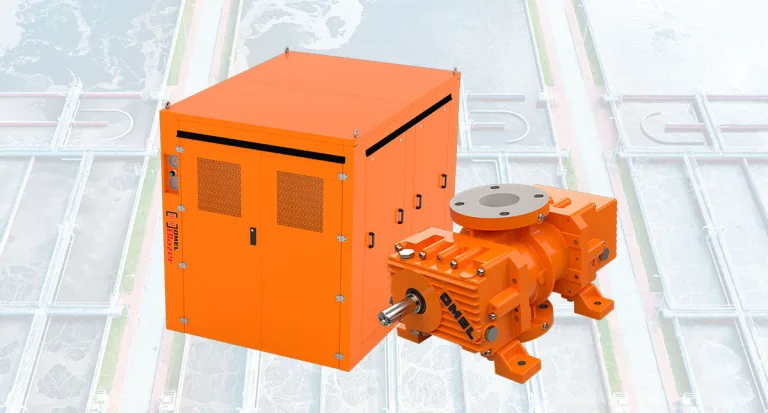

Discover more OMEL products

OMEL offers a wide range of high-quality products for various applications. Products offered include centrifugal pumps, vacuum pumps, metering pumps, roots blowers, ring compressors, rotameters, vacuum systems, and pinch valves.

Advantages of purchasing OMEL equipment

Fully national design and manufacturing

Original spare parts and ready delivery

Specialized technical assistance

OMEL Engineering available to develop custom projects

Technical support and online service

Service throughout the country