Vacuum Systems

In addition to liquid ring vacuum pumps, OMEL designs and manufactures Vacuum Systems for specific applications.

Vacuum systems are specially designed to meet the strict requirements and conditions required by various industrial processes. In addition to ISO 9001 certification, the company is able to meet all standards required for the supply of these sets, including standards of petrochemical companies and other energy companies.

Project Features

Vacuum system is a generic term for an arrangement of equipment used to generate a vacuum.

The comparative analysis for choosing between the various vacuum systems available for a given application must take into account all the technical factors of the application that requires it, as well as the economic factors.

The two main factors that affect the final selection of a vacuum system are the suction pressure that must be maintained or achieved in the process and the flow rate to be sucked.

However, several other factors must be checked, depending on the process where the vacuum system will be installed, and among them we can mention:

The tolerance of the vacuum system in sucking up solid or liquid materials;

The response of the vacuum system to a possible increase in air intake;

Interference in the performance of the vacuum system from a possible increase in discharge pressure;

System operation in corrosive or explosive environments.

Settings

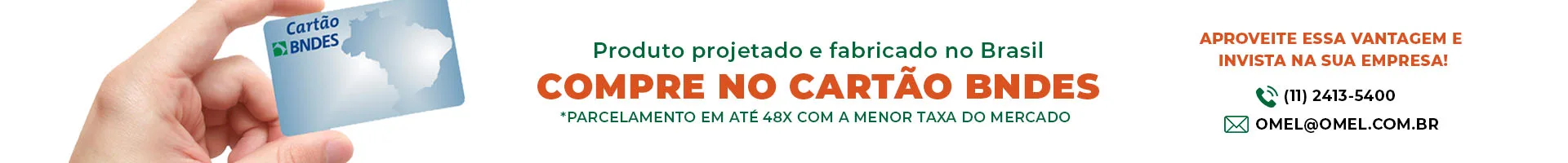

Configuration 01

Liquid ring vacuum pumps, heat exchangers, separators for sealing liquid, centrifugal pumps for extraction, piping and instrumentation, vacuum system for removing air from the turbine condenser at equipment start-up.

Configuration 02

Liquid ring vacuum pumps, steam or atmospheric ejectors, condensers, recirculation separators, heat exchangers, centrifugal pumps, piping and instrumentation Vacuum system for maintaining absolute pressure of the order of 10 mm Hg abs in a chemical reactor.

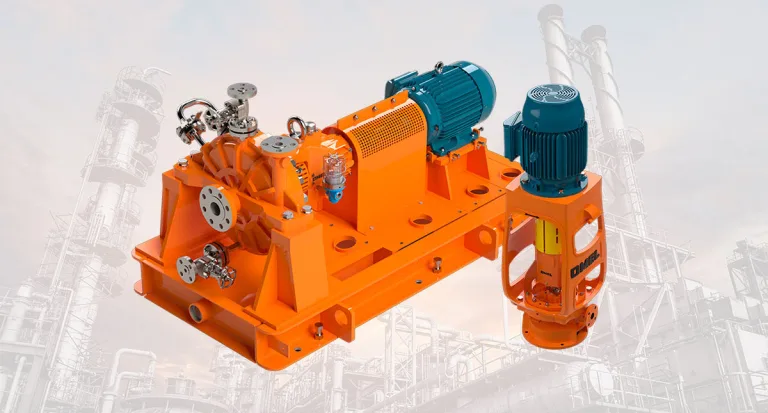

Configuration 03

Liquid ring vacuum pumps, Roots type vacuum pumps, recirculation separators, heat exchangers, centrifugal pumps, piping and instrumentation. Vacuum system for maintaining absolute pressure in chemical processes without the use of steam and with recompression of the aspirated gases to a pressure above atmospheric.

OMEL Original Parts and Technical Assistance

Get your pump repaired by the manufacturer!

By choosing OMEL’s after-sales service, you can count on the factory warranty, trained technicians, complete reports to diagnose the need for replacement parts, automated processes for manufacturing high-quality parts, and final performance tests to release pumps and instruments. With the safety, durability, and reliability of products repaired by OMEL, you will have excellent results in your industrial process and reduced operating costs.

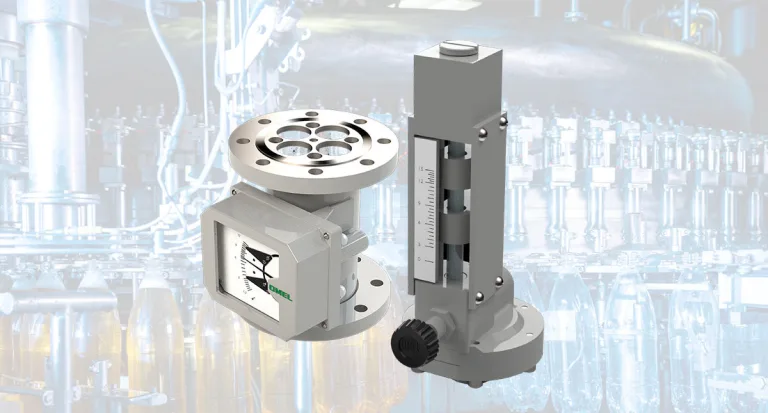

Discover more OMEL products

OMEL offers a wide range of high-quality products for various applications. Products offered include centrifugal pumps, vacuum pumps, metering pumps, roots blowers, ring compressors, rotameters, vacuum systems, and pinch valves.

Advantages of purchasing OMEL equipment

Fully national design and manufacturing

Original spare parts and ready delivery

Specialized technical assistance

OMEL Engineering available to develop custom projects

Technical support and online service

Service throughout the country