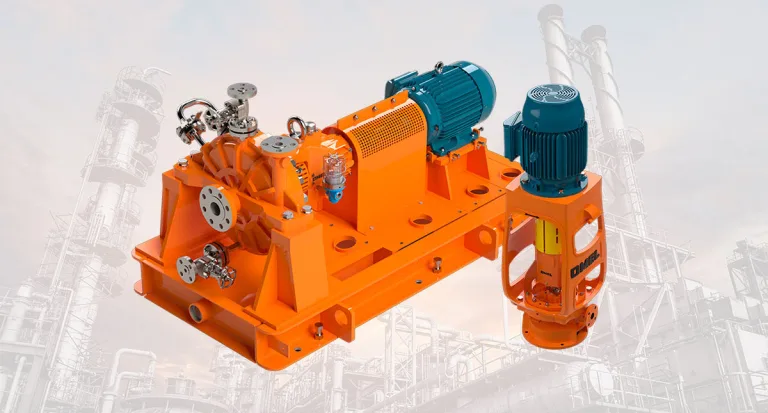

BLN/MV Vacuum Pump

Single-stage vacuum pumps with rotors between bearings and sealed by gaskets or mechanical seals.

Operational Parameters

Capacity: _____________________ up to 10.700 m3/h

Vacuum: ___________________________ up to 160 torr

Project Features

- The BLN/MV series liquid ring vacuum pump operates with auxiliary liquid (usually water) in a controlled quantity. As the rotor rotates eccentrically inside the casing, the liquid is driven by centrifugal force to the periphery of the casing. The rotor blades are immersed in the liquid ring, which is formed up to the level of the hub of the ring at a point on the periphery of the ring, with only the tips of their blades immersed at the opposite end of the ring. As the rotor blades, which are fully immersed, rotate, only their tips are immersed in the liquid ring, creating an empty space in the cavities between two consecutive blades. These cavities coincide with the inlet port through which air or process gases are induced. In a similar but reversed sequence, the air or gases are expelled through the outlet port of the side plate at the other end. The degree of vacuum achieved depends on the energy supplied to the liquid by the rotor speed and the characteristics of the auxiliary liquid used.

- Sealing by gaskets or mechanical seals;

- BLN/MV series liquid ring vacuum pumps are composed of sides, rotors, and eccentric body;

- They have eccentric intermediate elements made of carbon steel and a chrome steel shaft;

- The pumps can be manufactured in stainless steel ASTM A 744 Gr.CF8 and CF8M (AISI 304 and 316), subject to consultation for other special alloys or mixed materials.

Advantages

- When sucking dry or saturated gases, it allows the entry of liquids that may be entrained;

- Reaches a vacuum of 30 mbar;

- Low noise and vibration levels.

Applications

- BLN/MV liquid ring vacuum pumps are used in a wide range of industrial processes where medium vacuums are used, such as degassing, cooking, deodorization, deaeration, concentration, condenser exhaustion, distillation, solvent recovery, plastic extrusion, vacuum filtration, centrifugal pump priming, vacuum packaging, among others, always subject to consultation.

OMEL Original Parts and Technical Assistance

Get your pump repaired by the manufacturer!

By choosing OMEL’s after-sales service, you can count on the factory warranty, trained technicians, complete reports to diagnose the need for replacement parts, automated processes for manufacturing high-quality parts, and final performance tests to release pumps and instruments. With the safety, durability, and reliability of products repaired by OMEL, you will have excellent results in your industrial process and reduced operating costs.

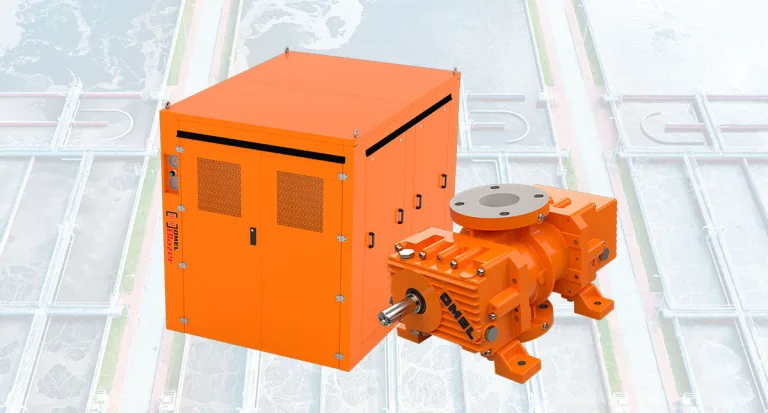

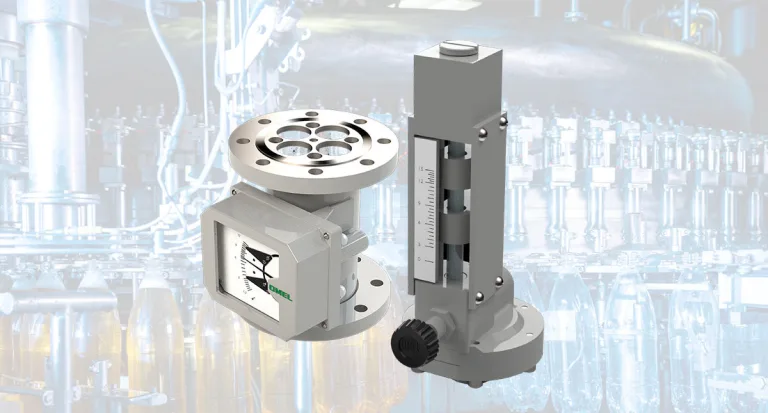

Discover more OMEL products

OMEL offers a wide range of high-quality products for various applications. Products offered include centrifugal pumps, vacuum pumps, metering pumps, roots blowers, ring compressors, rotameters, vacuum systems, and pinch valves.

Advantages of purchasing OMEL equipment

Fully national design and manufacturing

Original spare parts and ready delivery

Specialized technical assistance

OMEL Engineering available to develop custom projects

Technical support and online service

Service throughout the country